The Global Leader in High-Power Industrial Microwave Systems

Industrial Microwave Systems is the leading manufacturer of microwave heating and drying systems for food, liquids, and materials processing. For decades, IMS patented microwave technology has led the way in providing uniquely integrated system level solutions for sheet products, grains, chemicals, slurries, foods, pureés, powders, and various other materials.

Single-Mode | Multi-Mode | Custom Development & Modeling | Global Support

Drying | Heating | Tempering | Cooking | Bonding | Curing | Reacting | Cracking

2450 MHz | 915 MHz | 6kW to 1.2 MW | Transmitters | Generators | Magnetron Tubes

WR975 Waveguide | Circulators | Isoloators | Water Loads | Power Combiners | Tuners

Pasteurization | Sterilization | Microwave-Assisted Extraction | Solids | Liquids | Fluids

Ferrite Microwave Technologies

Ferrite Microwave Technologies (FMT) is the global leader in high-power microwave components and commercial-scale industrial microwave systems. FMT’s high-power RF and microwave component solutions focus on circulators, isolators, and duplexers. The systems manufactured by FMT offer advanced solutions for microwave cooking, drying, heating, and tempering. Ferrite Microwave Technologies also has a complete line of advanced 915 MHz microwave generators to support a wide variety of industrial processing and microwave R&D applications.

Industrial Microwave Systems

Industrial Microwave Systems (IMS) provides unique, patented, and specialized solutions for single mode microwave heating and drying. IMS standard or modularized system designs are available using either 915 MHz or 2450 MHz. Industrial Microwave Systems patented designs apply power to achieve rapid microwave heating and drying for a multitude of products, processes, and applications. IMS also provides in-house product trials, technical microwave research, and product development from its R&D lab.

Mega Industries

Mega Industries (MEGA) is a leading global provider of high-power waveguide, coaxial components, and ultra-high vacuum compatible microwave devices. MEGA’s high-power, low frequency microwave devices, components, and assemblies span from WR28 to WR2300. Their product line includes: loads, couplers, tuners, pressure windows, power combiners, rigid and flexible waveguides, and beyond. MEGA specializes in advanced microwave and RF component innovation and development.

Industrial Microwave Systems for Liquids and Fluids

IMS offers ultra-rapid microwave heating systems for liquids, fluids, biomaterials, chemicals, and more. Our R&D laboratory-scale 2450 MHz and commercial-scale 915 MHz microwave systems provide users with unique thermal processing abilities to assist with heating, drying, pasteurizing, sterilizing, microwave-assisted extraction, and more.

Chemicals

IMS has various processing solutions for thermally treating chemicals with microwave systems. This includes: resins, adhesives, biomaterials, rubber, plastics, and more.

Purées

Purées and other pumpable food products benefit greatly from microwave treatment. IMS has award-winning technology for its contributions to the purée marketplace.

Resources

We’re happy to welcome you to the world of microwaves. IMS has extensive applications knowledge, resources, unparalleled support and service, with a team dedicated to customer success. If you’re wondering about the potential application of industrial microwave systems for your process, welcome to IMS!

2450 MHz Industrial Microwave Systems

IMS 2450 MHz systems are an ideal solution for laboratory scale and R&D environments. Typically, these industrial microwave units are employed as research and test systems prior to scaling up operations to 915 MHz.

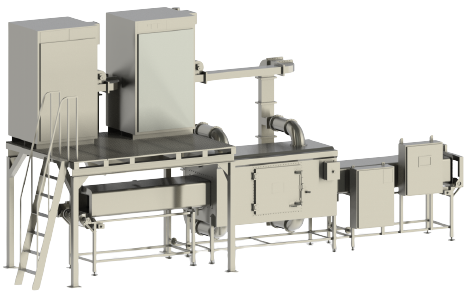

Microwave Drying and Heating of Foam, Wood, Paper and more

Industrial Microwave Systems offers a comprehensive line of microwave heating and drying systems for processing of continuous sheet materials, as well as loose, granular products. Our extensive industrial applications knowledge enables us to deliver advanced microwave processing solutions to manufacturers of various types of materials.

Industrial Microwave Generators

IMS offers a wide range of industrial microwave generators. These units offer consistent, reliable, and efficient microwave power generation. We have solutions that range from standalone units, to fully-integrated, container-based solutions for industrial microwave processing in outdoor settings.

Food Processing Systems for Meat, Grains, Purées, and more

Industrial Microwave Systems food processing solutions support a number of different food products. Our systems treat these products with microwaves, enabling procceses that include tempering, heating, pasteurizing, sterilizing, drying, and more. Uniquely, IMS manufactures its system technology for both solids and fluids.

Our Valued Customers and Partners