The Microwave Drying and Heating Systems by IMS are available in a diverse range of lab-scale and commercial-scale configurations. We offer decades of experience processing webs of fabric, sheets of paper, strands of foam, conveyed beds of material, pumpable chemicals, biomaterials, food products, and more. With extensive material processing knowledge, coupled with advanced microwave engineering, there is a high probability IMS can provide a cost-effective solution to fulfill your microwave drying and heating systems needs. As a result of our 2021 joining of the Microwave Techniques group, IMS has a combined product offering with Ferrite Microwave Technologies, making us the global leader in microwave technology.

Common Materials for Industrial Microwave Drying and Heating

The common materials for industrial microwave drying and heating include:

- Foams

- Powders

- Fossil Fuels

- Pulp and Paper

- Sludge Treatment

- Biomass and Biosolids

- Engineered Lumber (LVL)

- Liquids, Chemicals and Fluids

- Textiles and Nonwoven Fabrics

- Foods: Meats, Purees, Grains, and more

Exploring a new product or application? Speak with the experts at IMS.

IMS High Moisture Heating and Drying

Our patented high moisture applicators eliminate hot spots by uniformly heating thick materials of high moisture content that easily absorb microwave energy. These units offer an effective solution to challenging microwave heating and drying applications.

FMT Microwave Heating and Drying System

Ferrite Microwave Technologies MIP9 microwave heating and drying systems are used in food and other industrial settings. These units increase throughput up to 25% or greater, drastically improving the performance of an existing processing line.

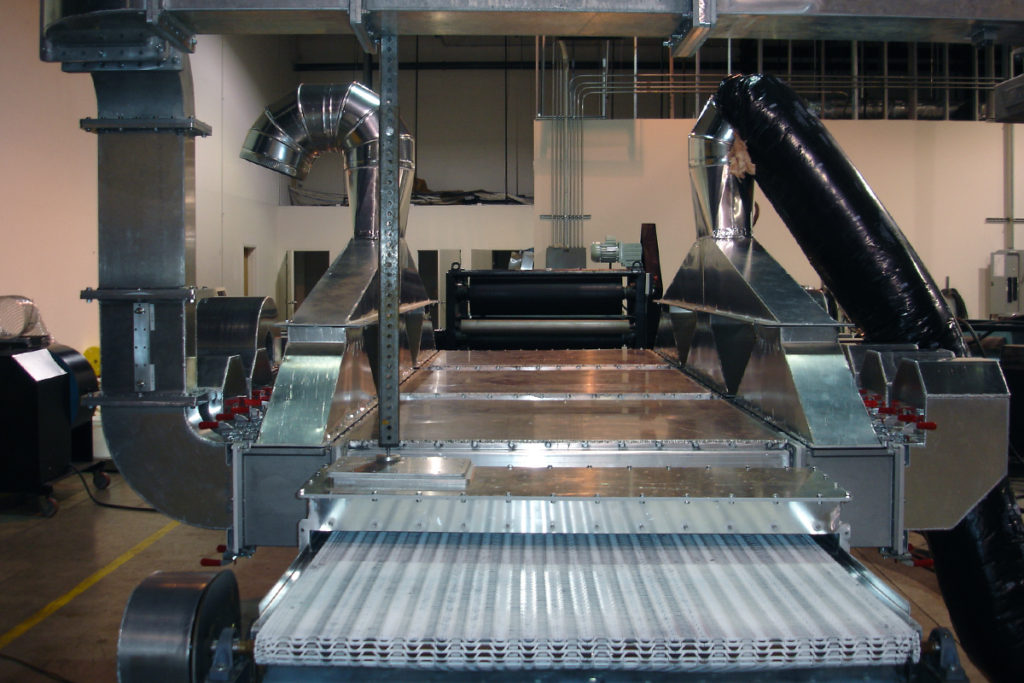

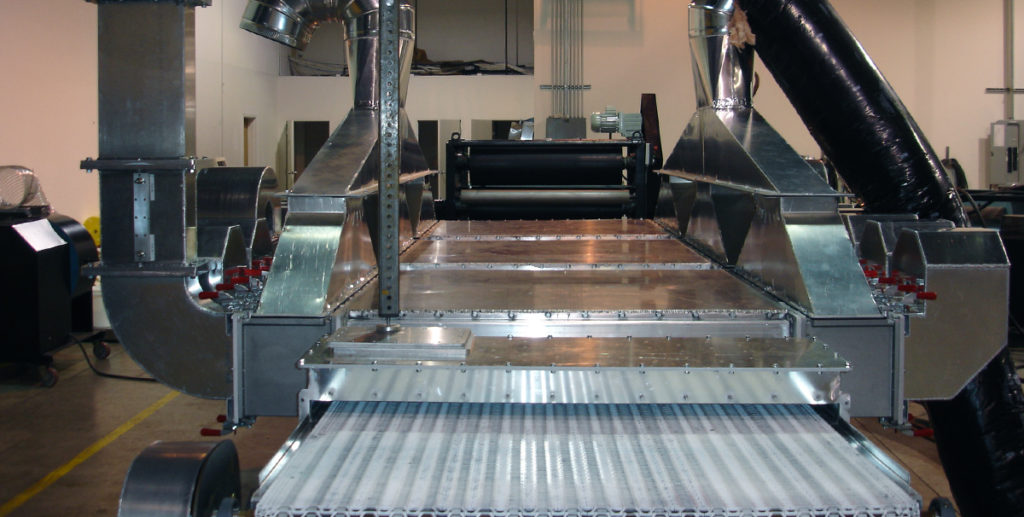

IMS Planar Heating and Drying

The IMS planar microwave heating and drying systems can offer a better alternative to conventional, re-circulated hot air dryers due to their best-in-class uniformity, efficiency, and thermal processing they demonstrate in many industrial processes.

2450 MHz Microwave Systems

IMS manufactures lab-scale 2450 MHz microwave drying and heating systems for low-volume, high-value applications. These units are typically for rapid heating and sterilization applications. This includes: food, beverage, and flavor processing, as well as for use in pharmaceutical and applications. As laboratory scale units, they are ideal for stand-alone bench top settings. Alternatively, they can integrate into existing conventional heating systems.

915 MHz Microwave Systems

IMS and Ferrite Microwave Technologies develop several standard and modularized 915 MHz microwave drying and heating systems. Whether clients are seeking solutions for chemicals heating, beverage processing, treatment of building materials, or drying textiles – we have deep experience and understanding of working with an assortment of materials. Commercial-scale units available in single- and multi-mode configuration.

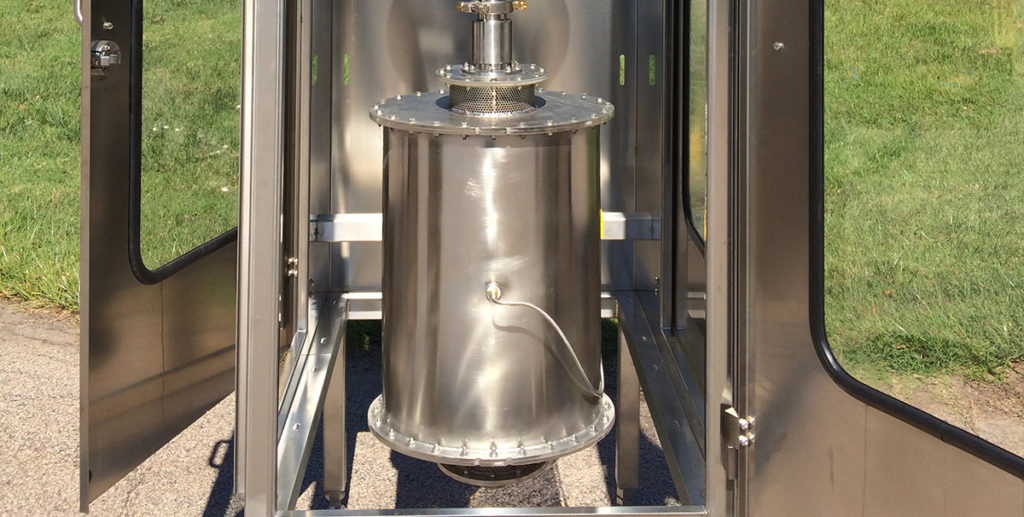

Solutions for Fluids, Pumpable Foods & Chemicals

Cylindrical heating technology by IMS provides uniform and continuous flow heating for foods, beverages, nutraceuticals, aseptic products, gels, biomaterials, and more. These specially designed heating systems uniquely provide microwave energy to pumpable materials flowing through a pipe.