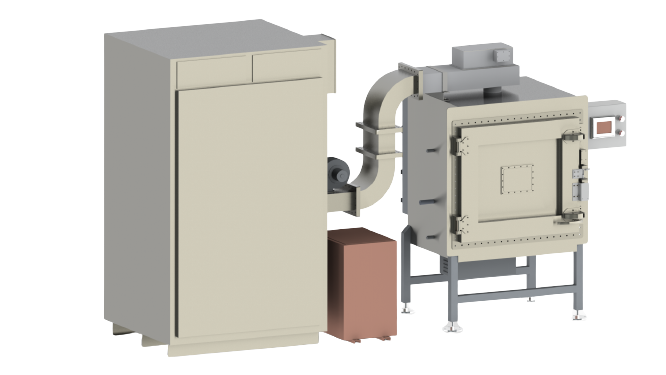

The MIP-4 Batch Microwave Oven by Industrial Microwave Systems (IMS) is a tempering unit made for small-volume, fast-paced food processing. The oven allows for optimal heating and uniform tempering in on-demand settings. This unit automatically brings the temperature of frozen foods up to between 22° and 29°F (-2°C). It can process up to 1,500 lbs. (680.4 kilograms) of product per hour. When using solutions like the MIP-4 Batch Microwave Oven, clients often experience the benefits of space savings, more preditable final temperature attainment, with higher quality and yield.

MIP-4 Batch Microwave Oven:

Unique Features

The MIP-4 offers users the most advanced technology in the industrial microwave industry. One feature of the oven is its unique rotary table, which provides consistent application of microwave heat to products with a low starting temperature.

In addition, it comes equipped with precise computer controls. This allows for management of processing variables, while providing exact increases in temperature towards the final target. The MIP-4 also utilizes user-friendly interface via digital displays. These provide status information such as actual versus set point power, fault diagnosis, and more.

Lastly, the batch oven features power driven by industry-leading microwave generator technology. Although the complete microwave system comes with a 75 kilowatt generator, it is control-limited at 35 kilowatts.

Specifications & Product Details

The following specifications apply to our Batch Microwave Oven:

| Frequency: | 915 MHz |

| Generator Power: | 35 kilowatts |

| Oven Size: | 3′ x 4′ (0.9 m x 1.3 m) |

| Heating: | 120,000 BTUs per 1 hour |

| Throughput (per hour): | 1,500 pounds (680.4 kg) |

| Product Example: | 50 lb. box of beef tempers in 60 seconds |

10 Reasons to Use A Batch Microwave Oven

Below, we’ve compiled a list of ways we’ve seen batch microwave ovens positively impact our customers’ processes.

1. Enhanced product quality.

2. Greater final overall yields.

3. More control over temperature.

4. A cleaner working environment.

5. Much faster results than water or air thawing.

6. Better safety for production team members and processors.

7. Consumers get a product with better taste and more protein.

8. Less risk of impurities, especially those caused by pollutants in the air.

9. More savings of space, when compared to traditional processing solutions.

10. Less labor costs, as there is less effort put into product handling or disposal of waste.

Curious about your product?

As part of our ongoing research and development, we offer in-person tempering trials for prospective clients. We’re always happy to discuss the potential application of microwave treatment for certain products.