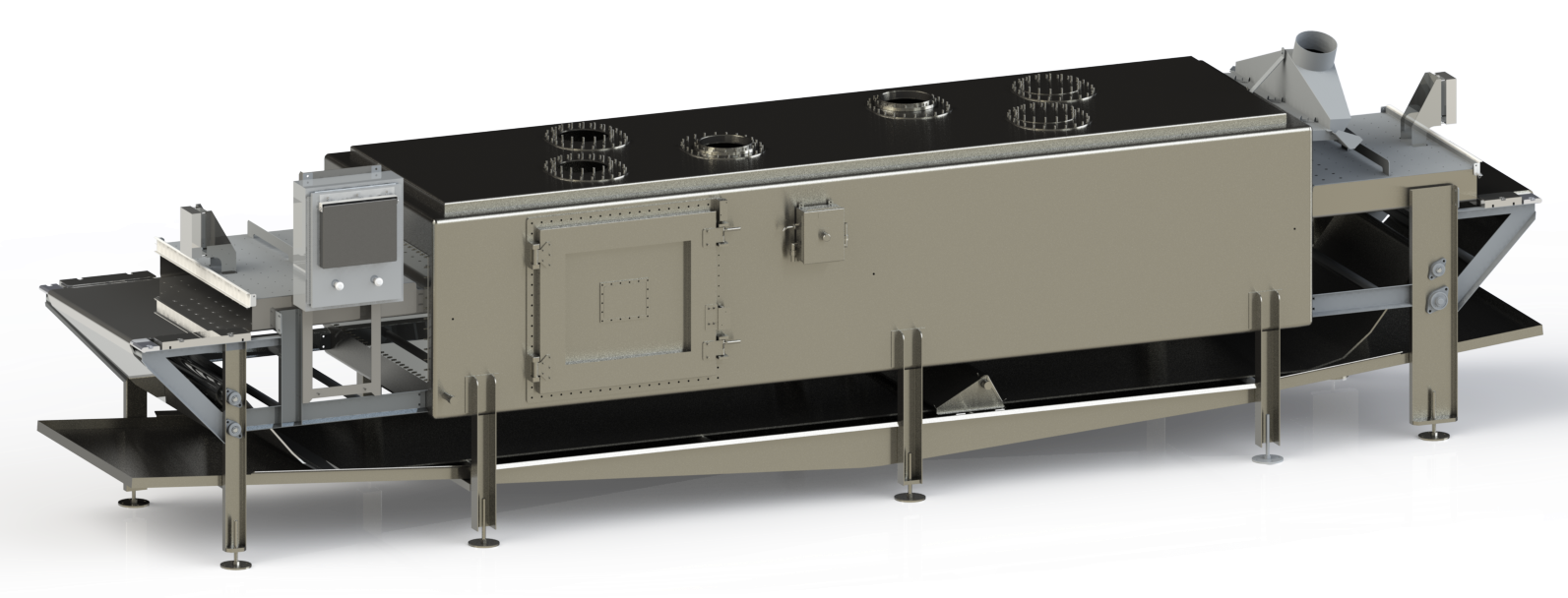

The MIP-9 Industrial Microwave Heating & Drying System by IMS is a versatile microwave system used for food and materials processing. With increases in throughput of up to 25%, the MIP-9 can dramatically improve the performance of any existing cooking or production line. A highly flexible system, it can boost heat and evaporate water from materials.

Features of the MIP-9 Microwave Heating & Drying System

As the applications for the MIP-9 industrial microwave heating & drying system steadily expand, so too, do its features. We make adjustments and fine-tune our designs to fit the exact application, product, facility, or other processing variable requirements. Although our systems are customer-specific, a few features of the standard MIP-9 design include:

- Features half and full product detection, plus arc sensing

- System consists of a 15′ (4.57m) multimode cavity, constructed of stainless steel

- The cavity offers 2 access doors for easy sanitation, system check-up, and routine maintenace

- One angled bottom pan, which leads to a pipe system for simple waste distribution or collection

- The cavity comes equipped with two rotary feeds (1 top, 1 bottom) to enhance microwave energy distribution

- To prevent any leakage into the surrounding work areas, suppression tunnels are found on both the input and output

General Specifications

The following specifications apply to our standard MIP-9 industrial microwave heating & drying system:

| Microwave Frequency: | 915 MHz |

| Microwave Power: | 75 to 300 kW |

| Oven & Transmitter Material: | Heavy Duty Stainless Steel |

| Transport Belt Width: | 36 inches (91.44 cm) |

| Standard Tunnel Bed Accomodation: | 34 inches x 3 inches (86 cm x 8 cm) |

| Typical Products: | Foam, Coal, Snack Foods, Biomass, Textiles, Spices, Grains, Wood |

| Customization Options: | Tunnel size, and others to meet certain customer requirements |

The Benefits of Microwave Heating and Drying

The benefits of microwave heating and drying are directly related to performance, throughput, and yield. In terms of performance, you will see better utilization of energy, and more processing flexibility throughout your facility.

With regards to throughput, you’ll see up to a 25% increase. Lastly, with reference to yield, there is less moisture driven from the outer portion of the product. This is mostly driven by raising the core temperature of the product, with less reliance on conductive heat transfer to reach minimum cook temperatures.

And, with throughput increased, you’ll expedite your product flow, leading to a higher final yield.

Benefits: Heating & Drying

| Heating | Drying |

|---|---|

| Increases yield | Increases in efficiency |

| Increases throughput | Increases in throughput |

| Less reliance on conductive heat transfer | Decreases in energy usage |

| Preferential denaturing of bones and bone matter | More flexibility through on-the-spot control |

Other Questions?

Check in with the experts! Our team is ready to help you understand the ways in which our technology can work for you!