Industrial Microwave Heating involves use of large-scale systems that apply microwave energy to heat food products and industrial materials. Food products commonly heated include: frozen meals, meats, grains, snacks, purées, fruits, vegetables, and more. Materials commony heated with microwaves include: lumber, wood, chemicals, fossil fuels, foam, rope, textiles, and other sheets or solids. Microwave heating supports food processes ranging from cooking, gelation, tempering, sterilization, and pasteurization. It also helps with drying, bonding, cracking, and reacting, among others.

Industrial Microwave Heating:

Systems & Technology

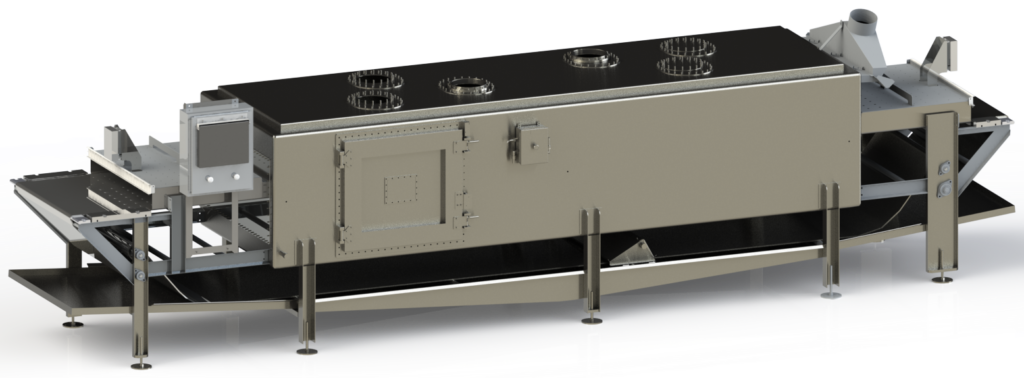

Through a combined product offering of IMS and FMT, our advanced technology with regards to industrial microwave heating is unparalleled. We develop patented technology that applies power to achieve rapid and uniform microwave heating for continuous processing on a production scale. Whether your process requires cylindrical technology (pumpable fluids through a pipe), or planar technology (on a belt through a tunnel), we can offer a variety of options.

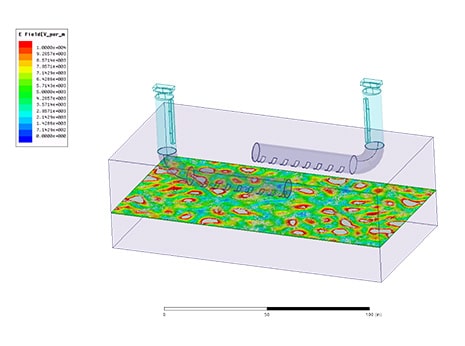

We utilize a state-of-the-art R&D test lab for product engineering and analysis. Microwave Studio, as well as other computer simulation tools, optimize system designs prior to product testing and manufacturing of the system.

Our technology supports processing materials such as: webs of fabric, sheets of paper, strands of foam, conveyed beds of material, pumpable chemicals, biomaterials, food products, and more.

An overview of our technology and capabilities includes:

- Commercial, lab-scale, and benchtop units available.

- Patented microwave feed technology for field uniformity.

- Patents for our applicators, thermal processing techniques, and more.

- Standard modularized systems are available using either 915 or 2450 MHz.

- Boost Heating Technology: raises the entire core temperature of the product.

- In-house product trials, technical support for third party tests, and customer rental equipment.

Common Heating Applications

Material manufacturers and food processors are the most frequent users of industrial microwave heating technology. These operations require treatment of their products prior to next-step processing or reaching end consumers.

Common product applications for industrial microwave heating technology includes:

| LIQUIDS AND FLUIDS | CONTINUOUS OR SHEET MATERIALS | FOODS AND BEVERAGES |

|---|---|---|

| Biofuels | Rope | Purées |

| Ionic Fluids | Foam | Soups |

| Biochemicals | Paper | Slurries |

| Petrochemicals | Fabric | Surimi |

| Multiphase Liquids | Textiles | Sauces |

| High-Viscosity Fluids | Nonwovens | Smoothies |

| Chemical Formulations | Insulation Materials | Meat and Poultry |

In addition to regularly working with the foods, bererages, liquids, and other materials – we often perform tests and R&D projects at our various test facilities in Nashua, NH and Garner, NC. We welcome you to schedule a visit to either facility to test your products. Or, instead, you may consider shipping us your product and we can run the tests ourselves. Either way, we’re always interested in testing new products and potential applications for industrial microwave heating.

Questions for us? Let’s set up a time to discuss your requirements!