If you’re new to industrial microwaves, you may be curious about the advantages, disadvantages, safety, economics, and alternatives. In this section, we’ll discuss each. Furthermore, we’ll lay out everything you need to know about industrial microwaves. If you find something unclear, or have a question about our equipment, please, don’t hesitate to reach out.

How Does Microwave Compare to Conventional Heating?

In conventional or surface heating, the process time is limited by the rate of heat flow into the body of material from the surface. This is determined by its specific heat, thermal conductivity, density and viscosity. Surface heating is not only slow, but also non-uniform. Especially with surfaces, edges and corners being much hotter than the inside of the material. Consequently, the quality of conventionally heated materials is variable and frequently inferior to the desired result.

Imperfect heating causes product rejections, wasted energy and extended process times that require large production areas devoted to ovens. Large ovens are slow to respond to needed temperature changes. They also take a long time to warm up and have high heat capacities and radiant losses. Their sluggish performance makes them slow to respond to changes in production requirements making their control difficult, subjective and expensive.

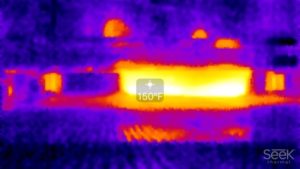

Conversely, with microwaves, heating the volume of a material at substantially the same rate is possible. This is known as volumetric heating. Energy transfers through the material electro-magnetically, not as a thermal heat flux. Therefore, the rate of heating is not limited. As a result, the uniformity of heat distribution greatly improves. Heating times reduce to less than one percent of that required using conventional techniques.

What Are the Advantages of Using Industrial Microwaves?

Volumetric heating is not dependent on heat transfer by conduction or convection. Thus, it is possible to use microwave heating for applications where conventional heat transfer is inadequate. One example is fluids containing particulates where the identical heating of solids and liquids is required to minimize over-processing. Another is for obtaining very low final moisture levels for product without over-drying.

Other advantages of industrial microwaves include:

- Microwaves generate higher power densities, enabling increased production speeds and decreased production costs.

- Microwave systems are more compact, requiring a smaller equipment space or footprint.

- Microwave energy is precisely controllable and can turn on and off instantly, eliminating the need for warm-up and cool-down.

- Lack of high temperature heating surfaces reduces product fouling in cylindrical microwave heaters. This increases production run times and reduces both cleaning times and chemical costs.

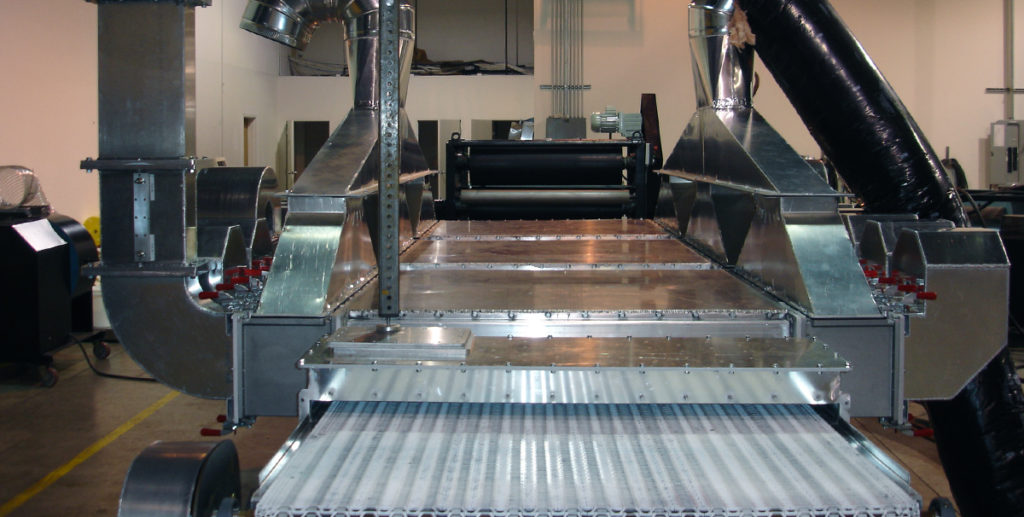

- Microwaves are a non-contact drying technology. IMS planar dryers in the textile industry reduce material finish marring, decrease drying stresses, and improve product quality.

- Microwave energy is selectively absorbed by areas of greater moisture. This results in more uniform temperature and moisture profiles, improved yields and enhanced product performance.

- The use of industrial microwave systems avoids combustible gaseous by-products, eliminating the need for environmental permits and improving working conditions.

What are the Disadvantages?

Historically, the primary technological drawback to using microwave energy for industrial processing has been the inability to create uniform energy distribution. If uniform energy distribution is not present, wet regions of the target material are underexposed, and other regions are overexposed. This is analogous to the hot spots and cold spots generated in your microwave oven at home. You may have seen this when heating or defrosting foods like a potato or frozen chicken.

Severe overexposure of non-uniform energy distribution may provide excessive focus of heat build up. This could result in burnt material or a fire hazard. The uniformity of distribution designed into IMS microwave equipment overcomes this problem.

Another disadvantage is the depth of penetration achievable using microwave energy. This is a function of microwave frequency, dielectric properties of the heated material and its temperature. As a general rule, the higher the frequency, the lower the depth of penetration.

Are Industrial Microwaves Safe?

Using patented applicator design geometries and unique choking mechanisms, IMS technology reduces microwave leakage from system entry and exit points. These are virtually non-detectable levels for both their planar and cylindrical heating systems. This poses no threat of electromagnetic radiation to the health and safety of equipment operators.

IMS heater and dryer designs operate at a level of electromagnetic emission that is twenty times more stringent than the IEEE/ANSI standard. As a further precaution, all IMS control systems have safety interlocks and leakage detectors. These shut down power instantaneously in the event of equipment malfunction or misuse.

Are Industrial Microwaves Expensive?

A common misconception is that microwave heating is always more expensive than heating by conventional techniques. The actual answer depends on the application and local utility costs. In some cases, microwaves can be more efficient than conventional systems, resulting in major savings in energy consumption and cost.

Learn more about calculating energy consumption, cost, and other requirements for industrial microwaves, here.

Pre-Dryers

When used as a Pre-Dryer in combination with conventional gas or oil heated air dryers, industrial microwaves allow overall production capacities to increase by 25 to 33%.

This is because the pre-dryer:

- Preheats moisture to the evaporative temperature.

- Can help to equalize the moisture level of product before the conventional dryer.

With current energy costs, the return on capital invested in an IMS pre-dryer has been as low as 12 to 24 months.

Post-Dryers

When used as a Post-Dryer in combination with conventional gas or oil-heated dryers, IMS microwave systems are more efficient than conventional dryers at achieving final moisture levels of less than 20%. This is because the lower the moisture level, the more difficult it is to drive moisture from the center of material to the surface by conventional heat conduction and convection processes.

An IMS post-dryer provides:

- Uniformity of moisture control and surface temperature of the final product.

- Higher production efficiency due to increased process speeds.

- Improved product quality resulting from reduced surface temperatures, compared with conventional post-dryer designs.

Return on capital invested in an IMS post-dryer has been as low as from 12 to 24 months.

Stand-Alone Dryers

In addition to the applications above, IMS planar units act as Stand-Alone Dryers. These may be the most economical solution. Especially where minimal equipment floor space or footprint is available for a new application. Or, when expansion of existing production facilities would require building modifications to accommodate a conventional drying system.

Cylindrical Heaters

In the case of heating a pumpable fluid using an IMS Cylindrical Heating System, the production cost of providing sensible heat transfer from microwave energy depends on the local cost of utilities. That can vary by a factor of five throughout North America. As a rough guide, this cost is expected to be approximately one third higher than using steam in a conventional heat exchanger.

However, this offsets by several factors, including:

- The reduced capital investment in steam boilers, steam trains, condensate collection and water treatment plant.

- The ability to use high power densities enables microwave heaters to substantially increase production rates.

- Uniform energy distribution minimizes fouling depositions in even the most viscous products. This is particularly important with thermally sensitive materials such as chemical polymers, food ingredients, nutraceuticals, biotech products & pharmaceuticals.

- For multiphase food products, hold times greatly reduce using IMS high temperature heaters. This is because the equilibration of hot and cold spots is virtually instantaneous. This is because the difference in their temperatures is minimal, unlike conventional heaters. Smaller hold tubes also reduce capital investment and operating costs for system pumps.

- With volumetric heating of multiphase products, solids loadings of 70% or higher can be processed, since the carrier fluid is not used as the primary heat delivery medium.

- The shorter residence times achievable with microwave heating improve product quality. Compared to conventional heating, IMS heated food products tend to retain a higher percentage of flavors and nutrients.

Before designing any commercial microwave heating or drying system, IMS recommends working with its customer. We prepare a customized Economic Value Analysis. This is based on the actual process specifications required.

Contact our industrial microwaves R&D team for further details.