The applications for industrial microwave systems continue to expand, with products successfully reacting to microwave treatment each day. As part of ongoing research and development, our in-house testing laboratory enables us to develop solutions for new products regularly. We have decades of experience processing webs of fabric, strands of foam, pumpable chemicals, biomaterials, food products, conveyed beds of material, sheets of paper, and beyond. With extensive industrial microwave applications knowledge, there is a high probability that IMS can immediately provide a cost-effective solution. If you have an emerging application, or require custom designs, we’re happy to partner and develop new solutions.

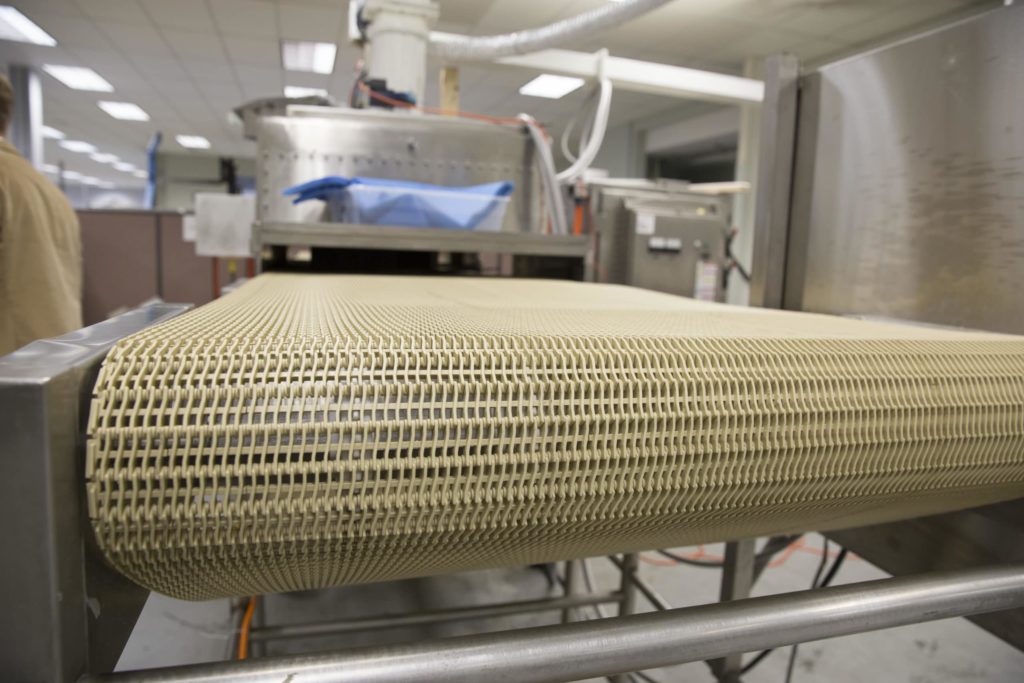

Food Processing

Industrial microwave technology is a centerpiece in the food processing industry. As new food products are developed and reach the market, we continue to refine our systems to meet the latest requirements for those new products. We offer solutions for tempering, defrosting, cooking, heating, pasteurizing, drying, and more.

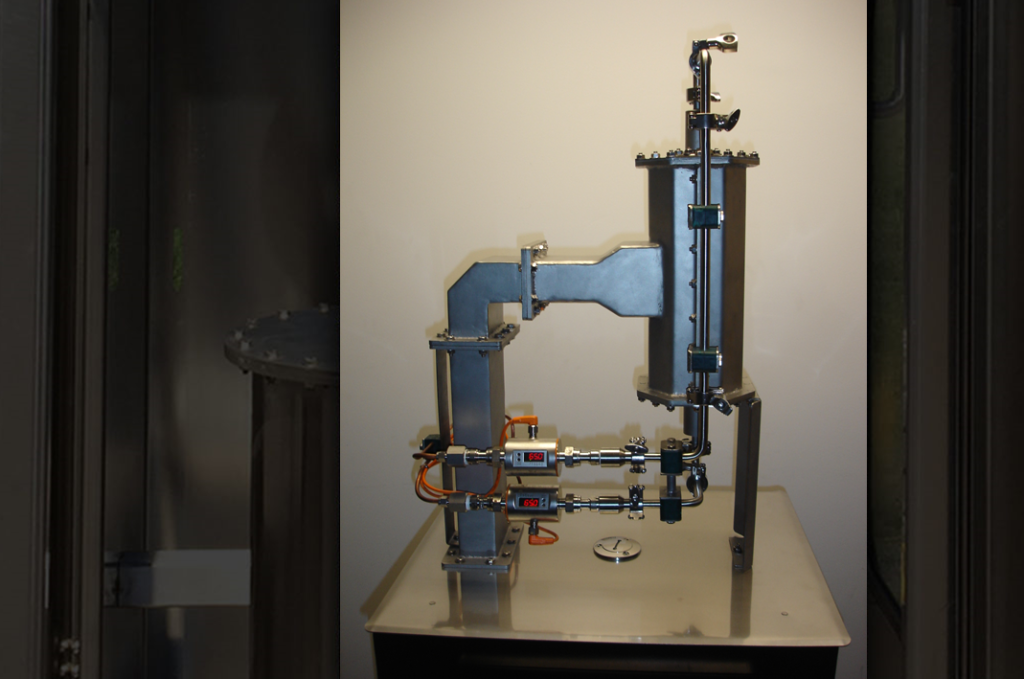

Chemicals Heating

For industrial microwave applications involving chemicals, heat is typically applied to initiate a reaction or change in state to the end product. Our technology often produces results that may be impossible to achieve with other surface heating technologies. Units are available for laboratory and commercial scale processing.

Beverage Processing

IMS technology features unique, ultra-rapid methods of heating asepctic and extended-shelf-life pumpable food products, beverages, and biomaterials. Industrial microwave applications and products that employ our technology include: cheese and pasta sauces, dairy and coffee based drinks, and over 60 other food products.

Microwave-Assisted Extraction

IMS Microwave-Assisted Extraction technology produces results that may be often to achieve with other microwave system technology. When compared to other processes, our MAE technology helps improve the yield and speed of a chemical extraction. IMS specialized Microwave-Assisted Extraction technology is used on products such as: biofuels, chitin, cellulose, oil, resins, pharmaceuticals, chemical formulations, and more.

Foam Drying

In foam manufacturing, one of the most important aspects of the process is drying the material. As a material that is consistent and transparent, treating foam with microwaves is fast, efficient, and proven. We have specialized applicator designs and patented feed technology for products containing high moisture levels.

Powder Drying

Most traditional drying equipment takes longer to dry powder, with less impressive results. In contrast, industrial microwaves uniformly apply energy to evaporate moisture from the product. Our systems have faster warm-up times with easier operation than other technologies, giving more control over the product.

Liquid Heating

Liquid heating with microwaves offers its users several benefits and creates superior end products. Benefits include: higher quality products with better taste, texture and nutrients, as well as the ability to deactivate enzymes that reduce product shelf life. In turn, you can expect reduced costs and longer production runs.

Wood Drying

Wood products are excellent candidates for microwave treatment. Typically, engineered wood such as LVL lumber involves spray-on adhesives. These liquid adhesives activate immediately when subjected to microwave energy. IMS has specialized systems for wood products in need of bonding, heating, or drying.

Fabrics Drying

IMS has extensive industrial microwave applications knowledge when it comes to processing fabrics, textiles, nonwovens, carpets, and more. Many of these materials benefit from the application of microwave power. Our systems apply energy in a way that exhibit excellent adhesive setting and color drying properties.

Purées Heating

IMS is a Food Technology Industrial Achievement Award winner for its collaborative efforts with the USDA, involving industrial microwave heating of purées. We developed the first commercial processes to adopt innovative microwave technology involving the aseptic processing and packaging of sweet potato purées.

New Microwave User?

If you’re new to the world of industrial microwaves, we highly recommend you read this. Here, you’ll find everything you need about industrial microwave systems. From advantages and safety, to applications and cost – we cover it all. If you are curious about industrial microwave applications, feel free to read this.

Custom Applications

If your product is new, IMS offers a variety of options. For new or custom applications, we provide computer modeling simulations, in-house product trials, technical support for third-party test facilities, customer rental equipment, and ongoing research support. To start, contact our development and testing team today.