Industrial Microwave Fabric Drying improves product quality, reduces costs, and increases drying speeds for textiles, fabrics, and nonwovens. By utilizing IMS technology, fabrics that require heating or drying benefit from pre-drying, post-drying or complete drying with retrofitted or standalone systems. Our heating and drying systems may retrofit onto existing conventional infrastructure as pre- or post-dryers to increase production speeds. IMS has several designs of commercialized industrial microwave fabric drying systems for knits, towels, yarn, rope, carpet, and other nonwovens.

Fabric Drying with Microwave Systems: Case Studies

The following examples demonstrate the benefits of using IMS technology for textiles, fabrics, and nonwovens:

Tubular Knit Fabrics

A California municipality and a local tubular knit manufacturer contracted IMS to provide a solution. IMS installed a 100 kW, 915 MHz, overhead, horizontal microwave system for pre-drying tubular knit fabrics. This installation was part of a Customer-Directed Energy Solutions Program that provides funding for electric customers to evaluate beneficial electro-technologies.

Installation and operation of the system demonstrated that drying speeds increased by 93%. This performance equates to the fabric absorbing 94% of the microwave energy generated. In addition, energy consumption, labor costs, and fixed costs were all reduced. The increase in throughput and reduced operating cost led to annual savings. This equated to a payback of less than six months.

Woven Fiberglass Fabrics

In another case, IMS was contracted to install an industrial microwave fabric drying system for a leading producer of woven fiberglass fabric. The system needed to dry one-half ounce per square yard to four and one-half ounces per square yard fabric after saturation through a size bath to a final moisture content of less than 0.2%.

The system also needed to eliminate fabric damage typically generated from the latent heat of conventional drying during the numerous stops and starts in the process. IMS accomplished these objectives, while also increasing process speeds and installing the system on a balcony with limited headroom.

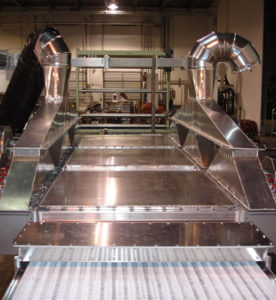

IMS installed a 100 kW, 915 MHz Planar Drying System oriented vertically in eight linear feet of headroom and two and one-half feet in the machine direction on an overhead platform. The system doubled drying speeds. It also eliminated off quality since there was no latent heat generated by the microwave energy during stops and starts. Overall, the payback to the customer was four months.

Overall, textiles applications benefit from the excellent color drying and adhesive setting properties of microwave power. Also, as a process that involves drying as well, microwave treatment has an added benefit.

Common Product Applications

Fabrics, textiles, and non-woven products that are typically dried with microwave systems include:

- Yarn

- Rope

- Knits

- Carpet

- Towels

- Insulation Materials

- Other non-woven fabrics

For information regarding IMS technology, please contact our support team. If you wish to learn more about our solutions with industrial microwave fabric drying, our R&D team is also readily available. We look forward to hearing from you!