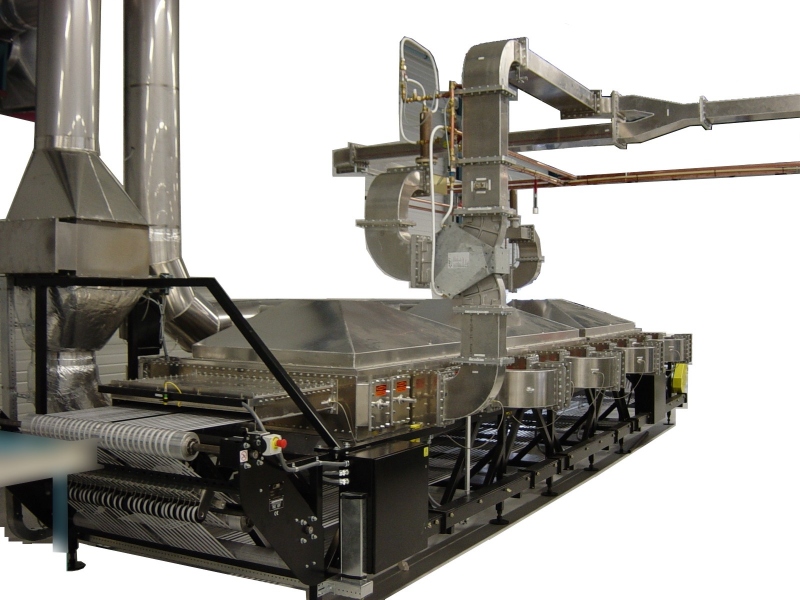

IMS manufactures industrial microwave foam drying systems that offer speed, process control, and rapid water evaporation from cured foams. Our patented designs uniformly apply microwave energy without overheating, or damaging the cell structure of foams. IMS drying units are capable of increasing production capacity up to 50%.

Benefits of Drying Foam with Industrial Microwaves

- Easy to clean, easy to service

- Precise product moisture control

- Reduction in time to market for new products

- Increased production capacity and line speeds

- Shrinkage characteristcs enable development of new products

- Electric power converted to microwave energy results in zero carbon emissions

Rapid Development of New Products

The unique characteristics of industrial microwave foam drying systems by IMS create an innovative tool for development of new products. Our systems accommodate wet foam up to 1.25″ (31.75mm) thick, by 46″ (1168mm) wide.

Standard units generate 100kW of microwave energy. They are capable of evaporating water up to 260 lbs. (118 kg) of water per hour. Consistent shrinkinage from uniform distribution of microwave energy ensures predictable end products.

When utilizing the industrial foam drying system, unique product characteristics are developed. This includes:

- Swell

- Density

- Water capacity

Industrial Microwave Systems for Foam Drying

The modular design of the IMS foam drying system allows for easy customization to fit specific customer needs. Standard units are available that meet requirements for most customers. The system offers easy accessibility, with clamped covers down the length of the machine. Very few moving components make for impressive reliability and minimal downtime.

Key replacement parts include: magnetron, conveyor belt, and drive components. Allen Bradley PLCs are standard on IMS systems. Remote diagnostic checks on the control system, performed via internet or modem access. This allows our service team to rapidly identify and fix any issues. In and out-of-warranty service contracts are available for systems.

Energy Efficiency & Utility Requirements

The IMS Foam Drying System runs exclusively on electricity. The microwave generator is extremely efficient converting electrical energy into microwave energy. Virtually all microwave power is absorbed by the water in the foam.

Additional power is required to power conveyor drives, fans, and air heaters.

Based on the standard 100kW system, the following utilities are required:

| 480VAC, 3 Phase, 60Hz, 200A for generator |

| 480VAC, 3 Phase, 60Hz, 150A for controls, fans, heaters, and drives |

| 34 gallons (129 Litres) of water per minute at 75° + 5F° (24° + 3°C) |

More Information

If you wish to inquire about the industrial microwave foam drying system, please contact us for more information. Our team is happy to discuss requirements and evaluate samples of your product, then prepare quotations for your review.