Industrial Microwave Food Processing is a method for cooking, tempering, sterilizing, drying, heating, and pasteurizing many food products. Uniquely, IMS has microwave systems that support processing both solid and liquid-based foods.

For loose, granular products such as grains, peanuts, cereals, pulses, or seeds, IMS offers food processing systems for drying. If your product is frozen, IMS offers a complete line of continuous and batch tempering systems. For items that need full cooking, such as bacon or poultry, we have several systems that provide complete cooking of foods, as well. In addition, IMS manufactures processing systems that help pasteurize or sterilize shelf-stable products, such as purees, liquid-type foods, and beverages. Overall, our microwave heating system technology for food processing is unparalleled.

Types of Industrial Microwave Food Processing Systems

The combination of Industrial Microwave Systems (IMS) and Ferrite Microwave Technologies (FMT) offers clients a wide range of industrial microwave food processing systems. This expansive product line, coupled with advanced resources, R&D, ongoing maintenance services, and unparalled support makes us the global leaders in high-power microwave.

Depending on the material or product, your throughput goals, and the intended process (i.e. heating, drying, cooking, gelation, tempering) there are a variety of industrial microwave systems. Although there are various designs of industrial microwave food processing systems, the list below summarizes some of the different types:

- 915 MHz

- 2450 MHz

- Multi-Mode

- Single-Mode

- Batch Ovens

- Indexing Ovens

- Microwave Dryers

- Microwave Heaters

- Boost Heating Systems

- Continuous Cooking Ovens

- Industrial Bacon Cooking Lines

- Continuous Tempering Tunnels

- Cylindrical Heating Systems for Liquids

Common Microwave Processes in the Food Industry

In the food processing industry, there are a number of different microwave processes. Typically, when our systems are involved, foods need to achieve some form of end-state before next step processing (i.e. slicing, dicing, molding, handling, packaging). The most common microwave processes in the food industry are:

- Drying

- Heating

- Cooking

- Gelation

- Sterilizing

- Extraction

- Defrosting

- Tempering

- Pasteurizing

- Boost Heating

Foods Often Processed with Industrial Microwave Systems

Similar to a household microwave, there are a number of foods that are proven to process exceedingly well in an industrial microwave. As the technology becomes more advanced, so too does the growth for the variety of products that react properly to microwave energy. Although there are far too many foodstuffs for us to list here, we’ve compiled a short list of food products and specific food manufacturing markets we reguarly support with our industrial microwave systems.

Solid Foods

- Fish

- Pork

- Meat

- Fruits

- Bacon

- Spices

- Grains

- Surimi

- Poultry

- Peanuts

- Seafood

- Meatballs

- Vegetables

- Snack foods

- Chicken wings

Liquid Based Foods

- Salsa

- Soups

- Surimi

- Slurries

- Soy milk

- Fish paste

- Smoothies

- Fruit purees

- Pasta sauces

- Cheese sauces

- Tomato products

- Vegetable purees

- Coffee-based drinks

- Sliced and diced foods

- Dairy-based beverages

Product and System Examples

IMS liquid-based food microwave processing system (above), fruit puree (below)

PUREES

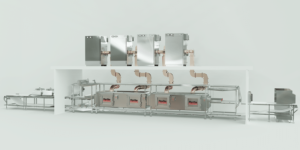

MIP-11 industial microwave continuous cooking oven (above), pre-cooked bacon (below)

BACON

MIP-12 industrial microwave tunnel (above), tempering frozen meat (below)

MEAT

MIP-10 batch oven (above), tempering chicken (below)

BONE-IN CHICKEN

Curious if your product is a fit for industrial microwave food processing?