Industrial Microwave Wood Drying applications, such as LVL lumber preparation, involves bonding layers of wood together with microwave heat. By activating the adhesives with microwave heat, our systems succesfully process various lumber and wood products. Applications like this where spray-on adhesives are used, and then later activated, are excellent candidates for microwave treatment. Liquid adhesives activate very well when subjected to microwave power.

Microwave Wood Drying Systems

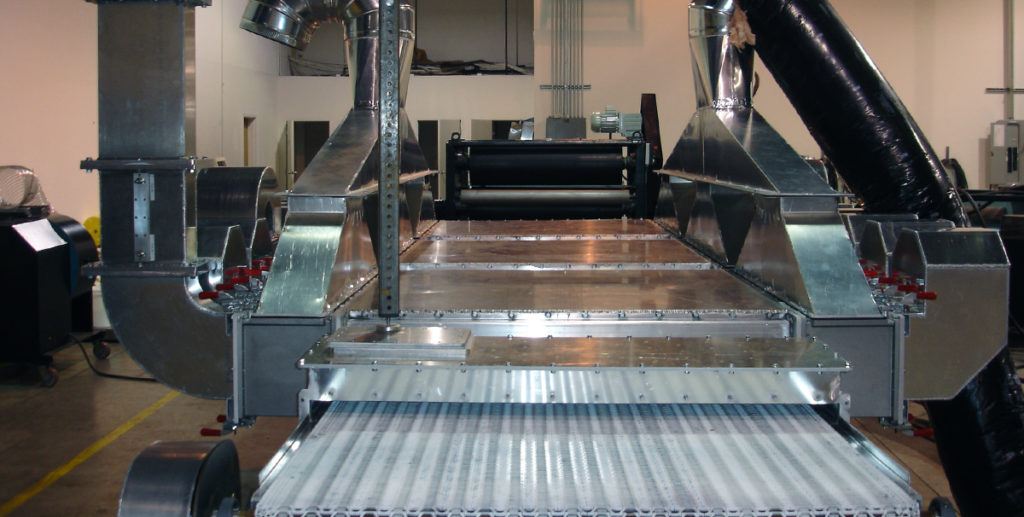

We’ve manufactured specialized microwave systems for laminated veneer lumber (LVL), in addition to other wood products. Microwave heating has several uses in the production of various wood products and related materials.

For processes involving heating or drying, in which there are many, microwave energy increasingly acts as a substitute for more traditional ovens fired by oil or gas. Our industrial microwave systems are widely used in LVL lumber processing.

Systems are often used in stand-alone heating and drying applications. However, we also see success with pre-heating materials prior to entering a conventional dryer. This also helps raise product moisture to its evaporative temperature. In addition, post-drying materials after a conventional dryer optimze the uniformity of final moisture content.

Microwave Technology for Wood Products: Benefits and Advantages

Industrial microwave wood drying systems and technology has several advantages over contentional dryers.

- Increasing production throughputs

- Rapid and uniform volumetric heating

- Much faster and more efficient than using kilns

- Preheating product to evaporative temperature

- Removing water from products with relatively low moisture content

- Environmentally friendly with no dangerous emissions or other hazards

- Products with less deformities as caused by overheating with other technology

Common Applications

While there are several different types of wood products, the most common applications involving microwaves include:

- Wood

- Timber

- Plywood

- Wood chips

- Engineered wood

- Laminated veneer lumber (LVL)

For other bonding and drying applications of this nature, a MIP-9 or MIP-11 system will likely suit the requirement.

In addition to these standard systems, we also offer modularized units. Both the ridged waveguide and wide applicators can heat and dry products with a width up to about 120 inches or 3000 mm. Since Industrial Microwave Systems (IMS) can offer three different types of planar applicators, it may provide a better solution than other multimode designs.

Questions about treating your product with microwaves? Contact our specialists today.