The use of industrial microwave systems produces new products that conventional heaters cannont through microwave assisted extraction. Many industrial, chemical, and bioformulations require the application of heat to initiate a reaction or change in state to achieve the required end product. By applying high-intensity electromagnetic energy to such formulations flowing in housings, pipes or tubes, our technology produces results that are difficult, or often impossible, to achieve with other heating technologies. When used in combination with ionic fluids, IMS technology and microwave assisted extraction greatly improves the speed and yield of a chemical extraction, compared to conventional processes.

Common Applications

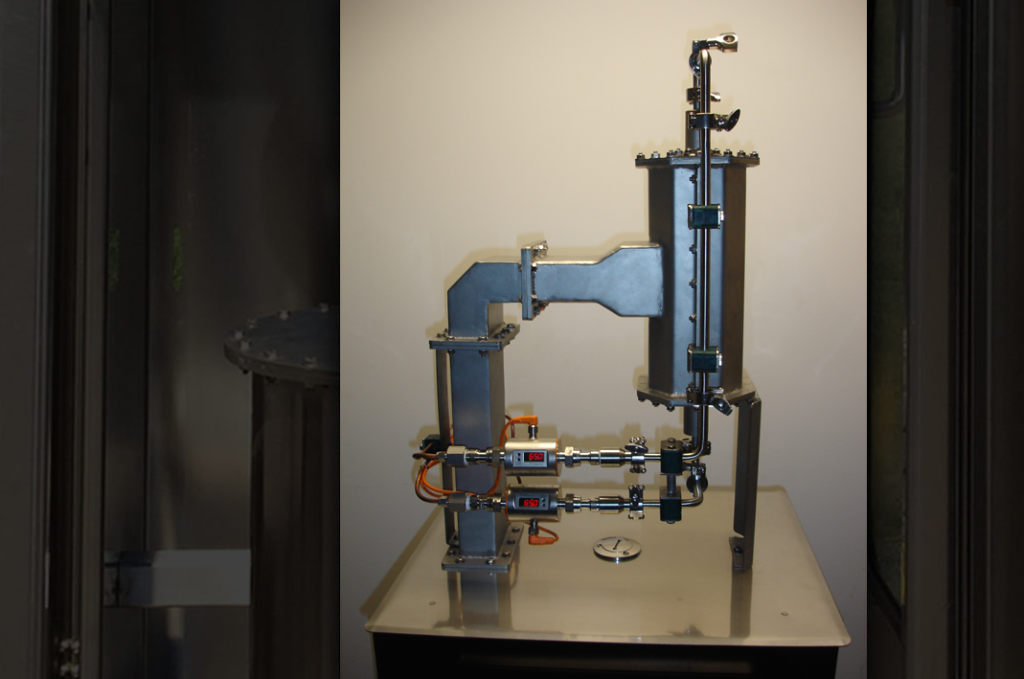

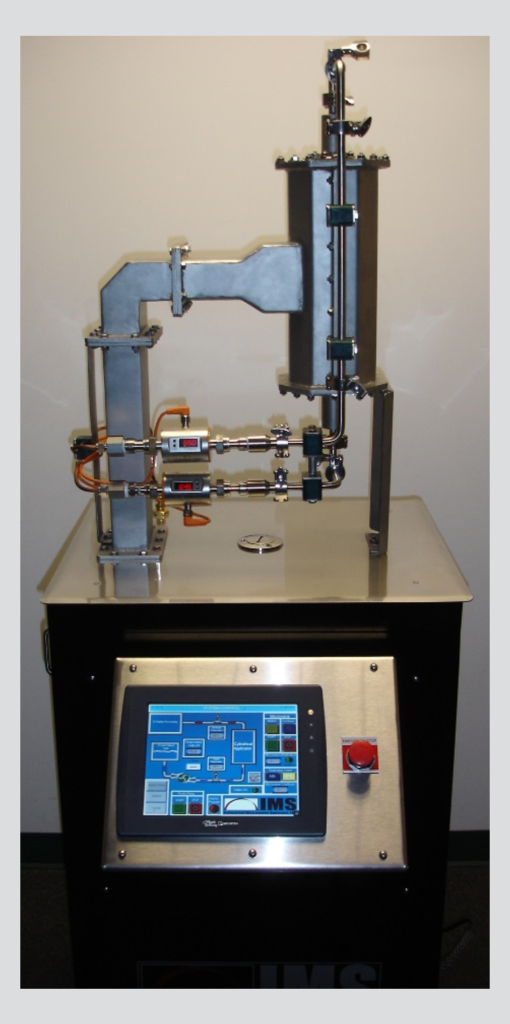

IMS in-line microwave heating systems for microwave assisted extraction have been successfully applied to a range of chemical and industrial process applications on both benchtop and commercial production scales. Although most of these processes are confidential to our end users, many were proven successful at our in-house testing facility, including:

- Biofuels

- Chemical formulations

- Polymeric resin heating

- Petrochemicals with ionic fluid

- Pharmaceutical ampule heater

- Chitin extraction with ionic fluid

- Nutraceuticals from plant extracts

- Plastic recycling using chemical solvent

- Extractions of oil from tar sands using ionic fluid

- Cellulose and other casings for protein emulsions

Benefits of IMS Microwave Assisted Extraction Technology

The benefits of the unique ultra-rapid in-line microwave heating and extraction technology that IMS provides include:

- Improved product quality resultuing from more even heating and reduced residence time

- Longer production runs due to reduction of scale or burn-on from hot surface processors

- Reduction or elimination of additives or catalysts due to faster reaction kinetics during a heating or curing process

- Microwave assisted extraction improves the speed and yield of a chemical extraction compared to other processes

Due to the volumentric ionic heating process, the center of any chemical or industrial product streatm may reach a higher temperature than the surrounding fluid. This is the exact opposite achieved when using conventional surface heaters. Instead, it enhances the thermal process.

Microwave Assisted Extraction: Case Studies

- A New York based company is using an IMS heater for the extraction of plant protein cells to maximize yield and product quality of its biopharmaceutical products.

- An Alabama based organization also uses MAE with ionic liquids to maximize the extraction of biochemicals from crustacean waste products.

As the pharmaceutical industry changes from batch production to continuous, IMS technology is expected to play an increasing role. Particularly, in the rapid sterilization of high-value, heat sensitive intravenous and other fluids.

Ready to discuss your requirements? Contact our dedicated experts today.