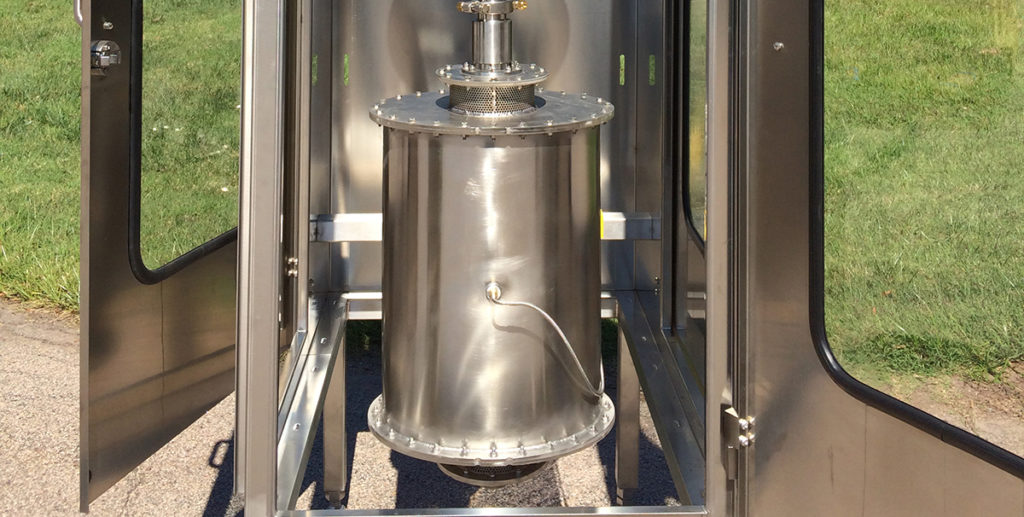

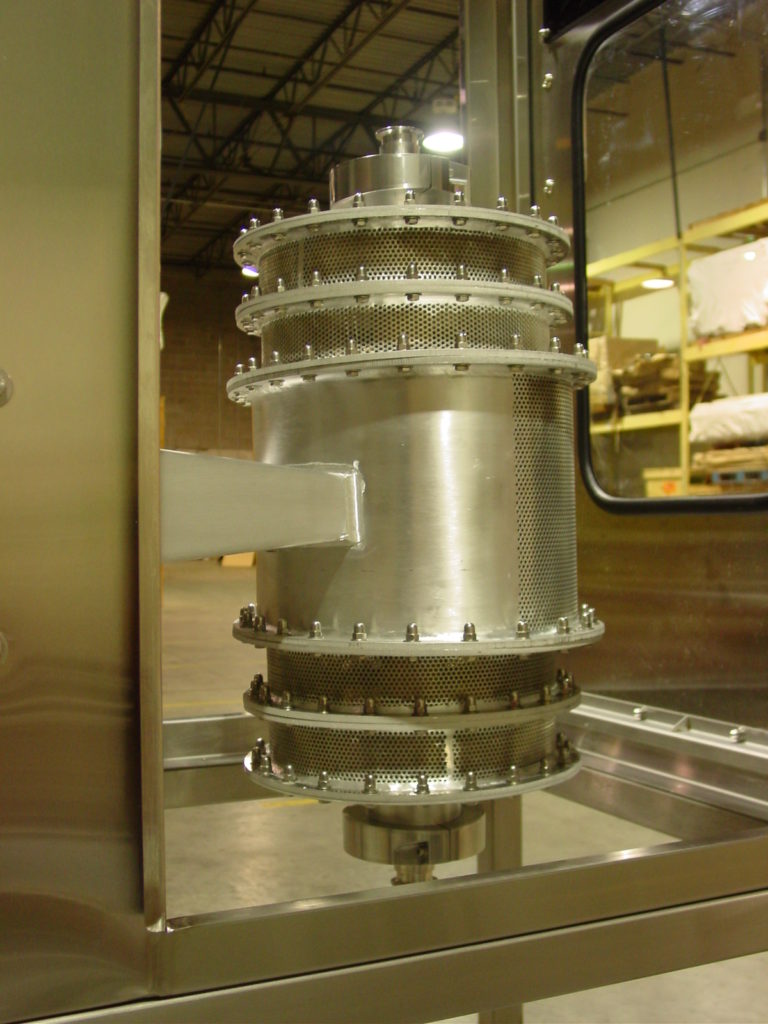

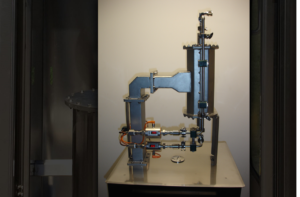

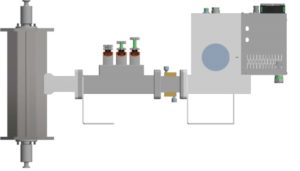

IMS manufactures Microwave Systems for Liquids and Fluids for heating, cooking, gelation, pasteurization, and sterilization applications. Their specific benefits and economic advantages are best achieved when applied to heat or shear sensitive, high viscosity, and multi-phase fluids. Each system heats product as it is pumped through a microwave-transparent heating tube. The tube is located at the center of the heating chamber, or applicator. These unique solutions provide continuous thermal processing of liquids, chemicals, pumpable foods, and other materials that demand precise temperature control. Overall, microwave liquid and fluid heating systems allow processors to improve their product cost-effectiveness and quality. In addition, they reduce equipment footprint and floor space. In some cases, they even create new or enhanced pumpable products. This is due to the cool wall surface temperature of the microwave heating tube. Products experience ultra-rapid heating and minimal residence times. Systems are available in laboratory and commercial scale.

Microwave Systems for Liquids, Fluids, Pumpable Foods, Beverages, Chemicals, and more

Industrial Microwave Systems (IMS) is the global leader in developing and manufacturing systems for various liquid and fluid heating applications. IMS provides solutions for continuous thermal processing of a variety of liquids. Our various processing units are best utilized for heat and shear sensitive, high-viscosity, and multiphase materials.

Benefits of Microwave Heating

Why heat liquids, fluids, and pumpable foods with our microwave systems?

- Cool tube wall surfaces, fast product heating, and short residence times minimize fouling deposits and degradation, increasing production run times

- Due to volumetric heating, center of particulate products achieve higher temperature than surrounding carrier fluid, enhancing thermal processing

- Superior products with minimal color change and better nutrient retention and organoleptic properties

- Requires minimal formulation changes to achieve even temperature distribution during heating

- Non-intrusive continuous process: liquid and fluid heating microwave systems are easy to control, clean in place, and inspect

- Combine with other technologies to optimize final heater retrofits or new production lines

- Standard design modules can be added to expand production throughout or increase heating range

- Low maintenance systems with no moving parts

Typical Products and Applications

What types of liquids, fluids, chemicals, and pumpable foods can you heat with industrial microwave systems?

| FOODS & BEVERAGES | CHEMICALS & FLUIDS |

|---|---|

| Salsa | Biofuels |

| Surimi | Cellulose |

| Soy milk | Biochemicals |

| Smoothies | Chemical formulations |

| Fruit purées | Polymeric resin heating |

| Pasta sauces | Extraction of oil with tar sands |

| Meat slurries | Pharmaceutical ampule heater |

| Cheese sauces | Petrochemicals with ionic fluids |

| Vegetable purées | Chitin extraction with ionic fluids |

| Dairy-based drinks | Plastic recycling using chemical solvent |

Questions about processing your product with microwaves?