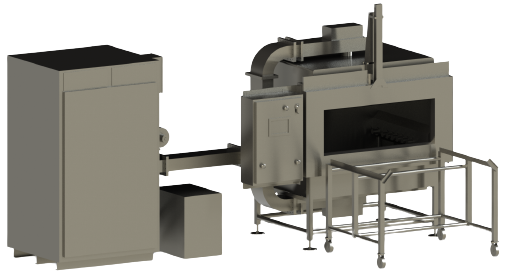

The MIP-10 Batch Microwave System by IMS is a precise tempering solution, able to process a load of 300 lbs. in just 4 minutes. It is highly capable of performing in a diverse range of settings. This microwave system tempers products such as: sausage, beef, seafood, bakery items, fruits, vegetables, and other frozen foods. It applies consistent, uniform, and efficient microwave power. The MIP-10 is most beneficial for tempering food products with low starting temperatures.

MIP-10: Overview & Specifications

To summarize an overview of our Batch Microwave System, we’ve also listed some specifications about the MIP-10 below.

| Basic System Oven Size: | 50″ x 42″ (1.3m x 1.1m) |

| Product Loading Accomodation: | 10″ (254mm) high containers |

| Loading Table Size: | 40″ x 48″ (1.02m x 1.22m) |

| Product Transport: | 5′ x 5′ (1.5m x 1.5m) heavy duty pallet on rollers |

| Oven & Generator Material: | Stainless Steel |

| Generator Power: | 75 kilowatts |

| Generator Frequency: | 915 MHz |

| Typical Product Start Temperature: | 0°F (-18°C) |

| Typical Product End Temperature: | 28°F (-2°C) |

| Typical Applications: | Potion-control plants, prepared food manufacturing, bakeries, and more |

Why Use Batch Microwave Systems?

There are many reasons to use batch microwave systems. Most of the reasoning centers around having better facility cleanliness, more process versatility, improved product quality, and higher final yields. Here, we’ve summarized some of the reasons why you should employ a batch microwave system in your facility:

- More accurate final target temperatures

- Better control and more concise processing time

- Much less liquid runs and drip formations in your facility

- Superior tasting product with higher protein compounds

- More savings on space and costs caused by product handling

- On-demand tempering leads to more versatility in your process

- Promotes better sanitation initiatives with reduced mess in the production line

Other Highlights of the MIP-10

- Generator utilizes integral FMT circulator. This helps provide longer magnetron tube life.

- Safe operating environment. The MIP-10 meets applicable safety standards (OSHA & HHS).

- Covered by 1 year warranty. In and out of warranty service available. All support is covered by our team of certified field technicians.

Questions for our team? Don’t hesitate to reach out!