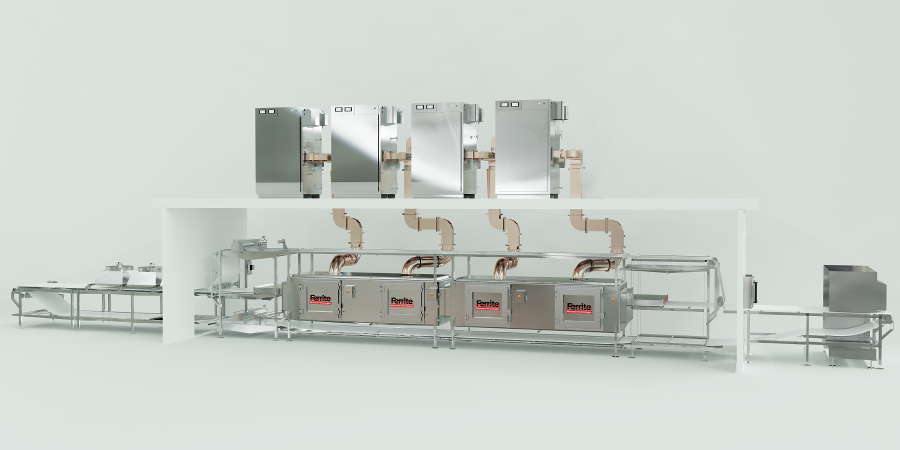

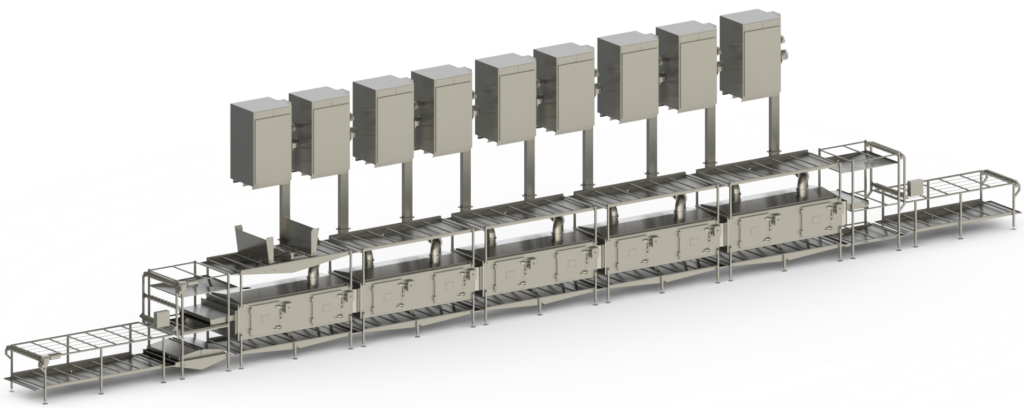

The MIP-11 Continuous Microwave Cooking Oven by IMS is a solution for complete microwave cooking, pre-heating, or post-heating of food. This oven system meets the requirements of several product applications. It is commonly utilized for bacon cooking. However, it is also used to process other meats, seafood, and poultry, among many other food products.

Continuous Microwave Cooking Oven:

Technical Specifications

As an overview of the specifications for the MIP-11, we’ve provided some details about the basic oven system below.

| Cooking Cavities Size: | 12′ x 4′ (3.7m x 1.3m) |

| Continuous Conveyor Width: | 3′ (0.9m) |

| System Product Opening Size: | 36″ x 3″ (864mm x 76mm) |

| Overall Length of Basic Single Cavity: | 24.5′ (7.5m) |

| Product Transport Belt Width: | 3′ (0.9m) |

| Product Accomodation (Thickness) | Products up to 3″ thick |

| Typical* Throughput: | 1800 lbs. (817 kilograms) |

| Generator Frequency: | 915 MHz |

| Single Generator Power Output: | 75 kW |

| Generators Per Cavity: | 1 or 2 |

| Total Microwave Power: | 75 kW to 600 kW+ |

| Typical Products: | Bacon, Meats, Poultry, Seafood, and other foods |

| Customization & Modularized Options: | System layouts designed to accomodate specific customer requirements |

Special Features of the MIP-11

As a highly customizable cooking oven system, the MIP-11 offers its users access to advanced microwave system technology. It uniformly and efficiently applies microwave energy to products, bringing forth consistent and proven results. For maximum flexibility, advanced computer controls offer users the management of speed and power settings.

Some special features of the MIP-11 continuous microwave cooking oven include:

- Remote troubleshooting software.

- System monitoring and tracking technology (FIMS).

- Advanced feed technology for even, uniform heating.

- Ability to pre-heat, post-heat, or fully cook food items.

- Expandable to increase production or throughput volumes.

- Modularized systems:

- Power Levels: from 75 to 600 kW.

- Lengths: from 24.5′ to 63.5′ (7.5m to 19.4m).

On-time delivery, detailed operator training, ongoing support, and complete assistance for a fully operational installation are hallmarks of our service. In addition, we also offer an array of options for the MIP-11 to optimize performance.

Other Options

- Heat Containment & Energy Efficiency: 2″ (50mm) thick, insulated cavity

- Removal of Product Residue & Grease: belt-cleaning system using high-pressure water

- Removal of Water & Excess Grease (before packaging): high-pressure, air-dry, blow-off, belt-cleaning system

Curious about other options? Check in with our microwave specialists!