The MIP-12 Continuous Microwave Tempering Oven by IMS is a tunnel-style solution, processing up to 17,000 lbs. (7700 kg) of product per hour. The oven system is able to improve product quality and final yield. In addition, it eliminates drip loss. This also helps retain flavors and proteins. As a result, better food reaches the consumer. Furthermore, with improved control over your product and processing procedures, you’ll see far less resultant mess in your facility.

MIP-12: Features

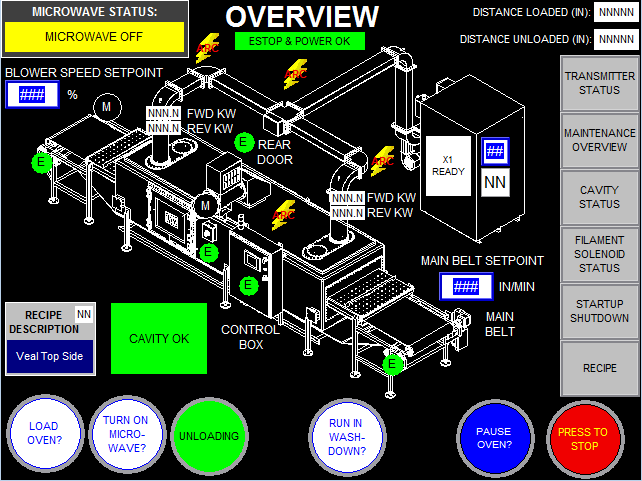

The MIP-12 features the most advanced system technology in the industrial microwave industry. Our technology provides user-friendly interface and industry-proven results. Features of the continuous microwave tempering oven include:

- Arc detection

- Emission sensors

- Safety interlocks on doors

- Remote regulation and troubleshooting

- Adjustable power and belt speed settings

- Generator features electrical isolation from oven

- Standard and custom tunnel sizes for certain products

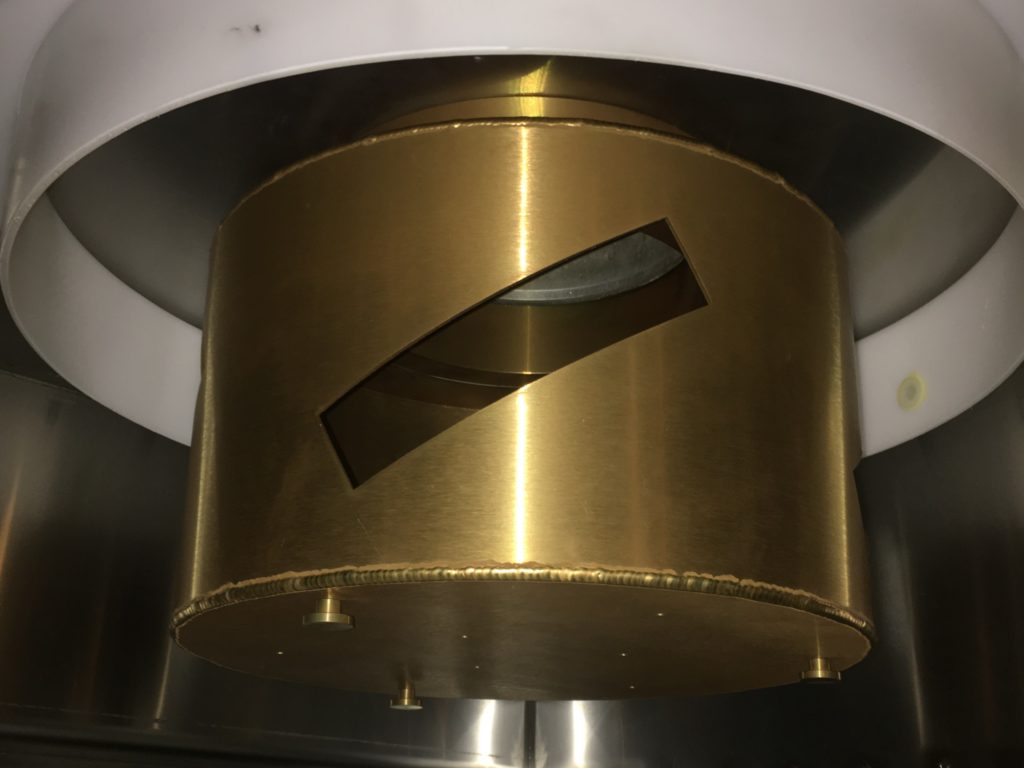

- Protected magnetron, provided by advanced circulator

- Ability to add generators to increase production output volumes

- Patented slotted cap feed design to further increase field uniformity

Continuous Microwave Tempering Oven: Specifications & Product Data

To provide a more detailed overview of the MIP-12, we’ve also listed specifications about the standard system below.

| Standard Tunnel Size: | 8′ x 4′ x 4′ (2.5m x 1.2m x 1.2m)* |

| Standard Product Accomodation: | 20 inch x 10 inch (50cm x 25cm) boxes* |

| Belt Width: | 20 inches* |

| Belt Type: | Positive drive, articulated, MW transparent |

| Generator Frequency: | 915 MHz |

| Single Generator Power: | 75 kilowatts |

| Number of Generators: | 1, 2, 3, or 4 |

| Combined Generator Power: | 300 kilowatts (max.) |

| Common Products: | Frozen Meats, Bakery Products, Fruits, Poultry, Seafood |

| Common Installation Locations: | Meat Plants, Seafood Processing Plants, Commercial Bakeries |

10 Reasons to Use a Continuous Microwave Tempering Oven

It may be daunting to think about replacing your current food processing infrastructure or equipment. But here, we put together a list of 10 reasons why using continuous microwave tempering ovens make more sense than other equipment.

1. Make your process more flexible.

2. Tightly control temperature increases.

3. Allow for a more predictable final temperature.

4. Bring your tempering time from days to minutes.

5. Your consumers and customers receive a better end product.

6. More precise control over product for downstream processing procedures.

7. Better space utilization as opposed to full rooms or racks dedicated to tempering

8. Determine your input and output production volumes on an adaptable or standardized basis.

9. Easier to keep up on sanitation and organization initiatives with less disorder on the production line.

10. Gives you peace of mind with remote regulation, troubleshooting, and ongoing support from our technicians.

Do you want to learn more about microwave system technology? Let our team help you!