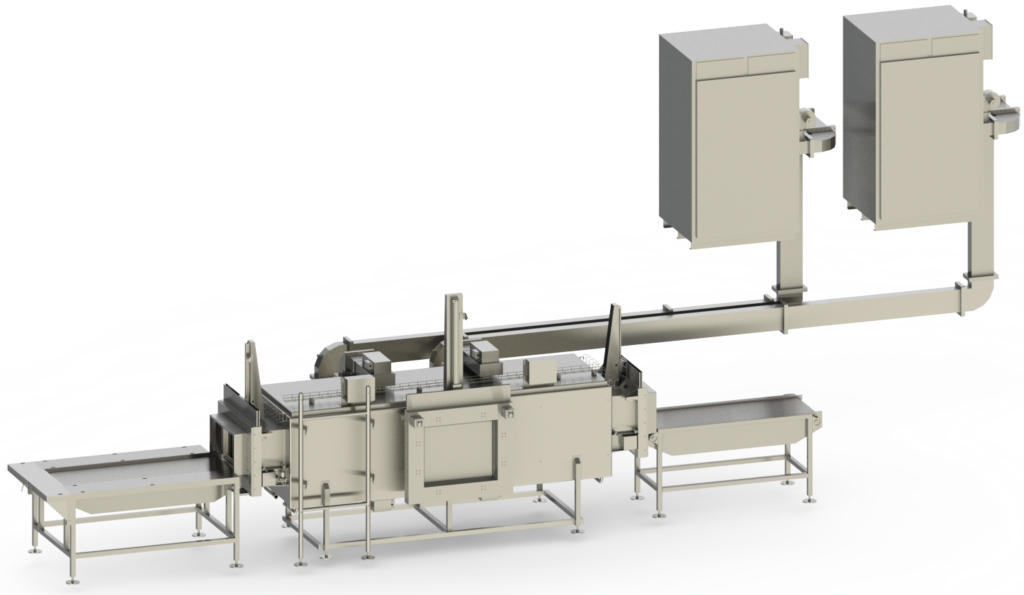

The MIP-8 Indexing Microwave Oven by Industrial Microwave Systems (IMS) is a CE-compliant tempering solution for a variety of frozen foods. It has the ability to temper 13,000 lbs. (5897 kg.) of 0°F (-18°C) product in just sixty minutes. In addition to its proven success with simplifying food production processes, the MIP-8 is easy to operate and maintain.

MIP-8 Indexing Tunnel Oven:

Overview & Specifications

To give an overview of the MIP-8, we’ve also listed some general specifications about the indexing microwave oven below.

| Standard Frequency: | 915 MHz |

| Operating Frequency Range: | 896 to 929 MHz |

| Basic System Cavity Length: | 4′ x 4′ x 8′ (1.22m x 1.22m x 2.44m) |

| Transport Belt Width: | 20-inch (other sizes available) |

| Microwave Power: | 75 to 225 kW |

| Generator Options: | 1, 2, or 3 total |

| Throughput: | 13,000 pounds (5897 kilograms) per hour |

| Typical Products: | Meats, Seafood, Poultry, Fruits, Breads |

| Customizable Options: | Systems designed to meet customer specifications |

Features & Advanced Technology

The standout feature of the MIP-8 is its compliance with CE requirements. Both the generator and process ovens feature interlocking access doors to provide a safe operating environment, exceeding most applicable government standards.

The indexing microwave oven system also features an internal oscillating conveyor. Once the system is turned on, the conveyor oscillates the product inside in a back-and-forth motion. This ensures uniform microwave heating. After the cycle completes, the product moves to the exit conveyor. From there, the product is ready for next-step handling.

Options & Highlights

We also offer various system options and techniques to provide extra protection and ease of use, such as:

- Arc detection

- Light curtains (optional)

- Emergency stop buttons

- Two-button gate lowering function

- Remote troubleshooting options via Ethernet

- System software provides easy operation and control

Why Use Indexing Microwave Ovens?

There are several beneficial reasons to using indexing microwave ovens. We’ve put together a short list below.

1. Facilitates tempering on-demand.

2. More precision with temperature attainment.

3. Takes up less space than dedicated rooms or racks.

4. Enables better processing flexibility throughout your entire facility.

5. Better control over product for next steps: forming, dicing, grinding, or slicing.

Our team is readily available if you wish to inquire about your product or discuss custom designs based on your requirements. We’re always happy to discuss the potential implementation of microwave systems into your facility!